analisi dei gas e delle emissioni nel settore navale Prove di laboratorio

Testing the fire reaction of materials and structures is a relevant aspect of the manufacturing process.

A.N.C.B. offers solutions and parts to laboratories and institutions in the following areas:

-Test equipments, fire testing systems and parts, accessories.

-Test management, data recording and reporting software for each standard.

-Temperature, pressure and many other sensors and transducer, also custom-made to comply with Standards’ requirements.

-Respiratory protection equipments and protective apparatuses when health hazards might arise during the test process (masks, respirators).

-Design and installation of fixed gas detection system, to protect the facility from leaks of gases (e.g. Propane) used in the fire tests.

- Service, calibration and support for Standard Test equipments.

Our portfolio of solution:

-Control and analysis cabinet for Electric Motors test bench:

Design of the sampling and analysis system (CO2 e O2 purity) for electric motors testing.

Developed for Nidec Industrial Solutions.

Scope of supply: sampling and analysis box with multi-channel sampling lines, channels selection and calibration features.

Certified calibration bottles.

-EN 50399 - Burning Behaviour of Bunched Cables:

We designed and built the complete testing apparatus.The 19″ instrument rack contains: paramagnetic Oxygen Analyser, infrared Carbon Dioxide Analyser, soot filter, moisture cold trap, pump and flow regulators forsample conditioning, smoke density measurement system.

A software was developed to record and elaborate data and to manage every stage of the test.

System developed for Metallurgica Bresciana S.p.A (Brescia, Italy).

-EN 13823 - Single Burning Item (SBI)

Design and implementation of the testing machine: gas pretreatment system, particle filters, sample cooler, paramagnetic Oxygen Analyser and infrared Carbon Dioxide Analyser, Smoke density measuring system.

Software managing:

- System calibration

- Pre-test checks

- EN 50399 test standard procedure

- Real-time data acquisition

- Report management.

System developed for RINA Fire Tests laboratory. (Genova, Italy).

-Fire Resistance Test Furnace ISO 834:

We supplied, wirede and connected all the custom-made certified thermocouple sensor,s for the test acquisition as well as for the burners’ temperature regulation.

We supplied the Data Acquisition system as well as other devices associated with the test.

Developed for RINA Fire Tests laboratory. (Genova, Italy).

-Test EN 1363:

We supply all special custom-made thermocouple sensors complete with the Inconel plate as requested by the Standard, as well as the copper disc measuring junction sensors.

RINA Fire Tests laboratory. (Genova, Italy).

-Test UNI ISO 1182 (REACTION TO FIRE TESTS FOR PRODUCTS - NON-COMBUSTIBILITY TEST)

Supplied alla sensors for the Test

RINA Fire Tests laboratory. (Genova, Italy).

-IMO FTP Code, Parte 5 e UNI ISO 9174.

REACTION TO FIRE OF PRODUCTS WHICH CAN BE HIT BY FLAME WITH RADIANT HEATING.

We created the custom Fume thermocouple assembly, the Compensator TC, the wiring and the mixing box, the Selector box for the software and all the accessories.

We also made the gas safety supervision system (fire check, valves, pressure switches interlock).

RINA Fire Tests laboratory and CSNI Scarl laboratory (Genova).

-IMO 2010 Test – FTP Code Part 5. and UNI 9174.

Control unit design and building. Control box with gas pressure adjustment, gauging and measuring of all varibles, blowers control, trolley start and stop, etc.

Gas safety supervision system (fire check, valves, pressure switches interlock).

RINA Fire Tests laboratory (Genova)

-EN 14225 Diving suits test

Part 1: Wet suits e Diving suits

Part 2: Dry suits.

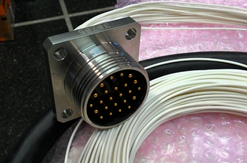

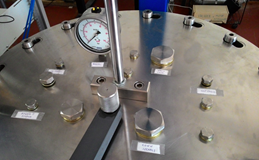

We designed and built the complete calorimetry apparatus. for the determination of the thermal insulation of the diving suit material. We built the sample Thermal System Assembly, supplied the temperature measuring system, pressure gauge, heaters, underwater connectors, interfacing to the control and data acquisition system.

19” Rack frame for all the components of the apparatus, including pneumatic cover lifting system, electronics, data acquisition and processing.

Calibration and commissioning

RINA Tests laboratory (Genova)