GDS | analisi casse di zavorra | gas infiammabili e tossici | Unità di campionamento gas Gas Sampling Systems

Gas Sampling Systems are designed to detect flammable and toxic gases in various areas of a ship, including ballast tanks, void spaces, compressor room, motor room and pump room.

A high-flow diaphragm pump carries the sample from the dangerous areas into the analyzer.

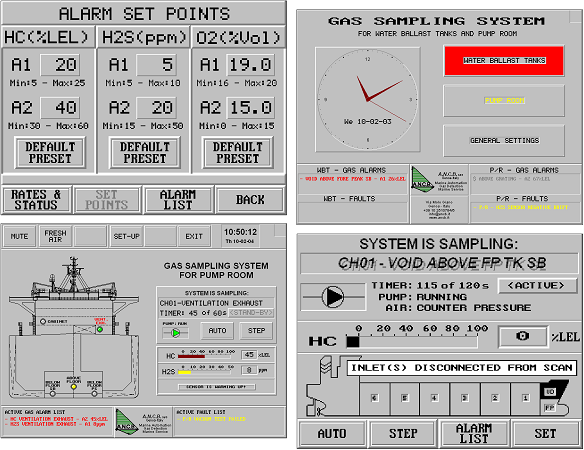

Samples are taken sequentially from a single measurement point, with a range of 0-100%L.E.L. Optionally, the system can be configured to detect hydrocarbons within a 0-100% Volume range by means of an Infrared sensor, and for the measurement of hydrogen sulphide (H2S) and/or oxygen, by means of electrochemical sensors.

Main functions and features:

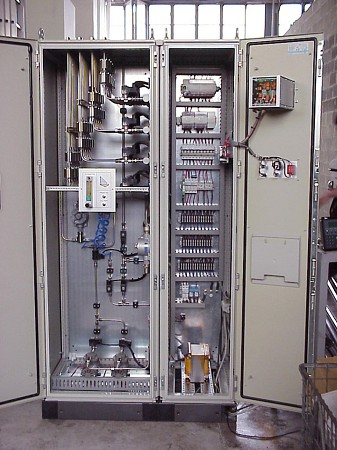

- Sampling unit enclosed in a gas-tight panel

- Graphic operator terminal as standard control unit

- Alphanumeric operator terminal as repeater unit

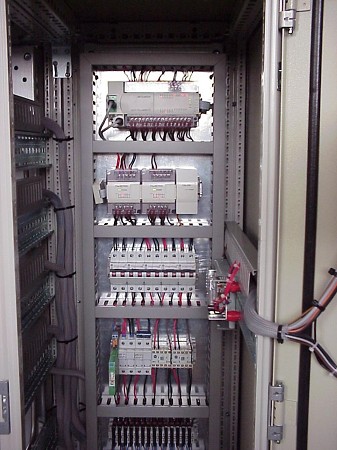

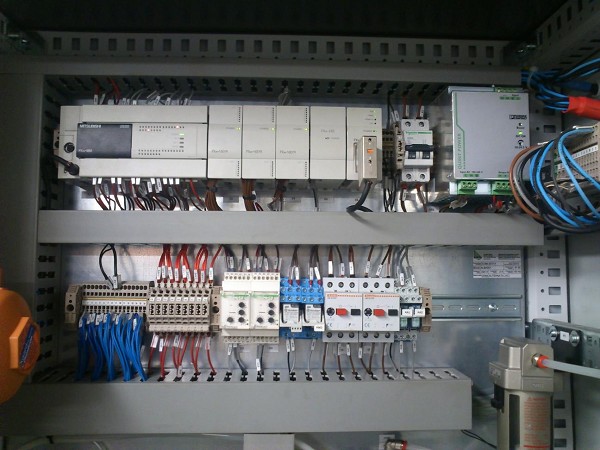

- Programmable Logic Controller (PLC)

- Sampling point manual or automatic scan

- Gas value reading and alarm generation

- Two gas alarm setpoints

- Sensor(s) fault alarm

- High flow sampling pump

- Auto test at start-up

- Flow fault alarm

- Sampling lines cleaning program

- Gas sensor(s) refreshing program

- Calibration by means of disposable span gas bottles

- Wet space channels exclusion

- Individual scan time setting

- Internal monitoring sampling point

- End-of-Line cones for wet spaces

- End-of-Line cones with filter for dry spaces

Options:

- Separate sampling and control units

- Extended or special graphic operator terminal

- Event printer

- Hydrogen Sulphide (H2S) measuring

- Oxygen measuring

- Hydrocarbon volume measuring by means of infrared sensor

- Counter-pressure air on sampling lines

- Pre-suction pump to reduce total scan cycle

- Panel’s customized color

- Tailored system configuration